The Mercedes EQB and EQS electric vehicles offer superior performance but require specialized care due to their advanced Battery Management Systems (BMS). While EQBs are more susceptible to everyday damage leading to common issues, EQS vehicles prioritize safety and efficiency with complex BMS technologies. Both require distinct repair approaches: meticulous checks for EQBs and deep understanding of high-voltage systems for EQS. Skilled technicians are essential, especially for collision repairs, as electric vehicle maintenance poses unique considerations. Consulting authorized dealers or trusted auto shops ensures proper handling of these specialized Mercedes battery management repairs.

In the ever-evolving landscape of electric vehicle (EV) technology, understanding the nuances between models is crucial for efficient maintenance. This article delves into the differences between Mercedes EQB and EQS, focusing on their unique features and distinct repair considerations. With a special emphasis on Mercedes battery management repair, we explore how the core difference in their battery systems impacts diagnostic processes and restoration of functionality. By navigating these distinctions, EV owners can ensure optimal care for their vehicles.

- Understanding Mercedes EQB and EQS: Unique Features and Repair Considerations

- Battery Management Systems: The Core Difference in Repair Needs

- Comparing Repair Processes: From Diagnosis to Restoration of Functionality

Understanding Mercedes EQB and EQS: Unique Features and Repair Considerations

The Mercedes EQB and EQS are electric vehicles (EVs) that bring cutting-edge technology to the roads. With their advanced battery management systems, these cars offer enhanced performance and efficiency compared to traditional gasoline models. The EQB, a compact SUV, and the EQS, a sleek sedan, both prioritize passenger comfort and safety with innovative driver assistance features. When it comes to repairs, however, each vehicle has its unique considerations.

Mercedes battery management repair is a critical aspect of maintaining these EVs. Unlike conventional cars, EV batteries require specialized care and expertise. Regular maintenance, such as checking battery voltage and temperature, ensures optimal performance. In case of damage or degradation, specific tools and procedures are needed for safe and effective repairs. It’s essential to consult authorized Mercedes dealers or trusted auto repair shops equipped with the latest technology to handle these unique repair needs, ensuring your EQB or EQS remains in top condition without issues from car collision repair scenarios.

Battery Management Systems: The Core Difference in Repair Needs

One of the core differences between EQB (Electric Quality Block) and EQS (Electric Vehicle System) vehicles in terms of repair needs lies in their Battery Management Systems (BMS). The BMS is a critical component that regulates, monitors, and controls the charging and discharging of the high-voltage battery packs. In an EQB vehicle, the BMS is typically designed with a focus on cost-effectiveness and simplicity. This means it’s often more susceptible to damage from everyday wear and tear or simple human error, leading to common issues like short circuits or overcharging that require specialized Mercedes battery management repair services.

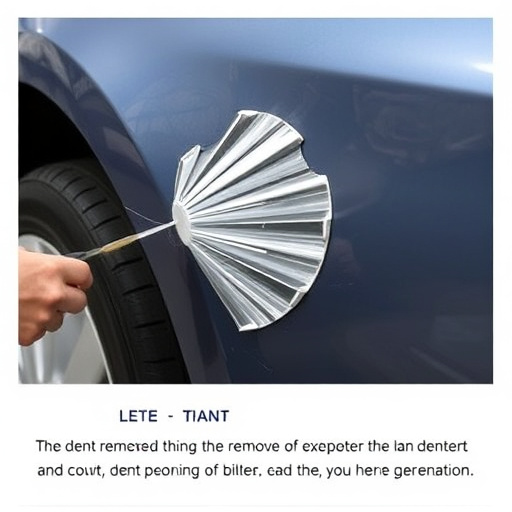

In contrast, EQS vehicles feature advanced BMS technologies that prioritize safety, efficiency, and longevity. These systems are designed to prevent catastrophic failures by implementing sophisticated algorithms for temperature control, voltage monitoring, and cell balancing. While this results in fewer potential issues requiring repair, the advanced nature of the technology means that when problems do arise—such as sensor malfunctions or communication errors—they require specialized auto repair services with expertise in electric vehicle diagnostics and repair, including paintless dent repair techniques if damage is minor.

Comparing Repair Processes: From Diagnosis to Restoration of Functionality

When it comes to Mercedes battery management repair, comparing EQB (Electric Quartz Battery) and EQS (Electric Performance System) repair processes reveals distinct approaches from diagnosis to restoring functionality. For EQB repairs, the process often involves meticulous checks of the battery system, given its intricate role in powering electric vehicles. Technicians utilize specialized diagnostic tools to pinpoint issues related to cell balance, voltage regulation, and connectivity within the battery management unit (BMU).

In contrast, EQS repairs demand a comprehensive understanding of the vehicle’s high-voltage architecture and its integration with various systems. The repair process may include replacement of faulty components like inverters or contactors, alongside adjustments to ensure optimal system performance after restoration. Car bodywork services might also be required if damage extends beyond the electrical components, emphasizing the need for skilled technicians who can navigate complex vehicle collision repairs involving electric vehicles’ unique considerations.

The distinct repair needs of the Mercedes EQB and EQS, driven primarily by their differing battery management systems (BMS), underscore the importance of specialized knowledge for effective maintenance. While both electric vehicles share many similarities with conventional cars, their advanced BMS necessitates unique diagnostic and repair processes. As the EV market continues to grow, understanding these differences is crucial for ensuring optimal performance, safety, and longevity of Mercedes’ e-mobile offerings. Effective battery management repairs will keep these innovative vehicles cruising smoothly into the future.